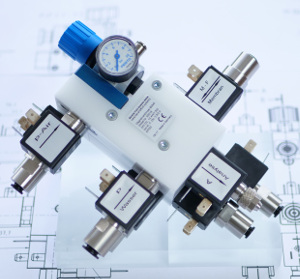

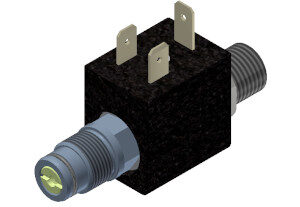

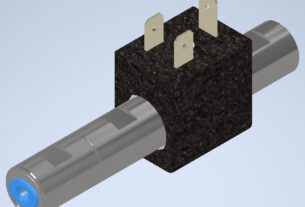

Dosing pumps and dosing valves from Bavaria Fluid Systems in Pforzheim are manufactured from turned parts. This is one of the basic prerequisites for subsequent precision and reproducibility when dosing liquids and gases. Here you can find out about the advantages of this precise manufacturing process:

- High dimensional accuracy of turned parts

Our turned parts are manufactured using modern CNC (Computerized Numerical Control) turning, which enables extremely accurate and repeatable dimensions. This precision is crucial for dosing pumps and dosing valves, as even the smallest deviations in shape and dimensions can affect the flow or dosing behavior. Tightly toleranced components such as spindles, sealing surfaces and housings ensure precise control of liquids and gases.

- Smooth surface quality

The turning process produces very smooth surfaces that minimize friction and wear. In dosing valves and dosing pumps, this reduces energy loss and enables finer control of flow or pressure ratios. Smooth surfaces also prevent particles from sticking, which improves reliability and durability.

- Precise fits and seals

Turned parts enable precise fits between moving and stationary components. These tight fits are important to prevent leaks and increase the efficiency of dosing pumps and dosing valves. Good fits also help to control flow paths and tolerance chains, resulting in precise dosing.

- Reproducibility and consistency

CNC turning allows components to be manufactured in series with consistent quality and precision. This allows dosing pumps and dosing valves to work consistently and dose precise quantities of liquids or gases, which is particularly important in automated processes or for sensitive applications.

- Flow optimization through precise geometries

Precise turned parts allow the production of optimal flow channels and internal geometries that ensure a uniform and controlled flow rate. This is particularly important in dosing valves in order to achieve precise regulation of the flow, e.g. in spray valves, needle valves or throttle valves.

- Less mechanical play

Components with minimal mechanical play enable more precise control of the movements of pump and valve components. This ensures precise control of dosing and ensures that movements and flows are immediate and without delay.

- Adaptation to different materials

Turned parts can be manufactured from a variety of materials, including metals, plastics and special alloys. As a result, dosing pumps and dosing valves can be optimized for special applications, e.g. for aggressive chemicals, high pressures or temperatures.

Conclusion:

Dosing valves and dosing pumps from Bavaria Fluid Systems in Pforzheim, which consist of precisely manufactured turned parts, ensure accurate dosing, as the exact geometry, smooth surfaces and low tolerances enable fine control of the flow and pressure. This is particularly important in applications such as the automobile industry, defence, chemical industry, food processing or medical technology.