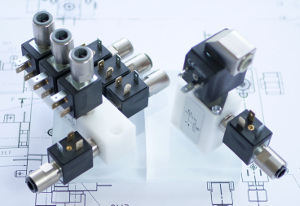

Hygienically clean in medical technology and pharmaceutical engineering with dead-space-free BFS inline solenoid valves.

Whether surgical instruments, hypodermic needles or in the production of pharmaceuticals – hygienic cleanliness is very important, especially in medical and pharmaceutical applications. Our BFS inline solenoid valves play an integral role in this.

For example, our valves control, regulate and meter the feed of the water boiler or the supply of steam at up to 180°C (superheated steam) for autoclaves in which medical instruments (syringes and scalpels) or liquids (nutrient media) are sterilized, or in steam blasters for dental laboratories.

One advantage of the design of our valves is that they have no dead spaces in which the fluid is not exchanged. Bacteria would multiply in dead spaces, which would then contaminate medical instruments.

In our BFS inline solenoid valves, however, all components in contact with the fluid are flushed with every switching operation, so that the valves continuously clean themselves and dirt or bacteria have no chance.