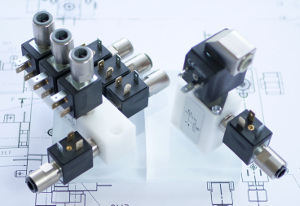

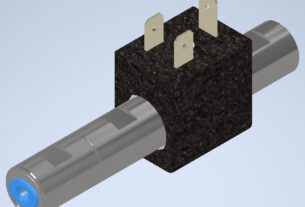

Fast-acting miniature inline dosing valves play a critical role in the food and beverage industry by providing precise, efficient, and hygienic control of fluids and ingredients. These valves are commonly used in automated production lines, helping to improve manufacturing processes and maintain product quality. Here are the applications and advantages of such valves:

Applications of Fast-Acting Miniature Inline Dosing Valves

- Ingredient Dosing: These valves are used to add precise amounts of ingredients such as flavors, vitamins, preservatives, and additives to base products, ensuring consistent recipes and quality control.

- Filling Systems: In beverage production, fast-acting valves are essential for filling liquids (e.g., water, juices, soft drinks, or alcoholic beverages) into bottles, cans, or other containers with high precision and speed.

- Mixing and Processing: They help control the addition of liquid components during food processing, such as mixing sauces, dough, or dressings, ensuring uniform consistency and proper blending.

- Carbonation Control: In the production of carbonated beverages, fast-acting valves ensure the precise introduction of CO₂, maintaining consistent carbonation levels in products like soft drinks and sparkling water.

- Packaging Processes: These valves are also used in packaging applications where liquids (such as sauces, syrups, or broths) are added to prepared foods or snacks, ensuring accurate dosing to meet packaging requirements.

Advantages of Fast-Acting Miniature Inline Dosing Valves

- Precise Dosing: These valves offer highly accurate control over liquid and ingredient dosing, ensuring consistency in product formulation and quality, which is essential in food and beverage production.

- Fast Response Time: The rapid switching capabilities of these valves enable quick adjustments to fluid flow, supporting high-speed production processes and reducing waste, which increases overall production efficiency.

- Compact Size: Their miniature design allows for easy integration into space-constrained or complex production environments, making them ideal for use in automated and highly efficient production lines.

- Hygienic Design: These valves are typically made from food-grade materials like stainless steel and sanitary plastics, ensuring they meet the strict hygiene standards of the food and beverage industry. They are also easy to clean, which reduces the risk of contamination.

- Reduced Product Waste: The precise control of liquid flow minimizes over-dosing and wastage of valuable ingredients, which leads to cost savings and more efficient use of resources.

- Versatility: Miniature dosing valves can handle a wide range of liquids, from low-viscosity fluids like water and carbonated beverages to thicker liquids like syrups, oils, and sauces, making them suitable for various applications in the food and beverage sector.

- Energy Efficiency: Their small size and quick response times mean these valves consume less energy compared to larger dosing systems, reducing operational costs and contributing to more sustainable production practices.

- Enhanced Automation: These valves are easily integrated into fully automated systems, allowing for greater process control, flexibility, and scalability in high-volume production environments. This results in faster production cycles and greater output without compromising on quality.

Summary

Fast-acting miniature inline dosing valves provide precise, efficient, and hygienic control in the food and beverage industry, offering significant advantages in terms of accuracy, speed, and resource savings. Their compact design, fast switching times, and versatility make them ideal for automated production lines, where maintaining product quality and meeting high production demands are critical. They also help reduce waste and operational costs, contributing to more efficient and sustainable food and beverage manufacturing processes.

For more information about our fast-acting miniature inline dosing valves and their applications in the food and beverage industry, please do not hesitate to contact us at Bavaria Fluid Systems.