Minimum quantity lubrication (MQL) is a technique for lubrication and cooling in various applications, such as in baking machines or in metalworking. Very small quantities of lubricant are applied directly to the machining point. Compared to conventional coolant and lubricant supply, MQL offers numerous advantages, especially when used in conjunction with fast-switching solenoid valves. Here are the applications and advantages of this combination:

Applications of minimum quantity lubrication

- Baking machines: 100,000 dough pieces (e.g. bread rolls) have to be formed per shift in the pockets of a rapidly rotating drum and removed again without sticking. Food oil is sprayed into each pocket in small quantities and in a very short time before the dough is introduced. This happens 100,000 times per shift. Thanks to our fast-switching solenoid valves, this saves oil, time and costs.

- Machining processes: MQL is often used in the machining of metals, such as turning, milling, drilling and grinding. It is particularly suitable for high-speed machining and for materials that are sensitive to overheating.

- Machine tools: MQL systems are integrated into modern machine tools to minimize the consumption of coolants and lubricants.

- Environmentally friendly production: MQL is used in manufacturing processes that aim to be sustainable and reduce pollutants.

Advantages of minimum quantity lubrication

- Reduced lubricant consumption: As only minimal quantities are used, consumption is drastically reduced, which saves costs and reduces the environmental impact.

- Improved workpiece quality: The precise application of lubricant directly to the machining point achieves better cooling and lubrication, resulting in a higher surface quality of the workpiece.

- Longer tool life: MQL reduces the thermal load on the tool and minimizes wear, which extends tool life.

- Cleaner working environment: As less lubricant is used, machines and workpieces are less contaminated. This makes cleaning and maintenance easier.

- Better visibility of the machining process: Compared to conventional cooling lubricants, which are often applied in large quantities, the machining point remains more visible with MQL, which facilitates process control.

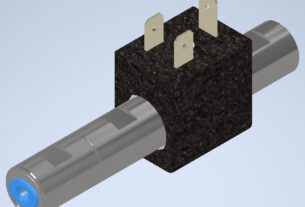

Advantages of a fast-acting solenoid valve

- Precise metering: Quick-acting solenoid valves enable very precise metering of the lubricant. Lubrication takes place precisely as required and only when the tool is engaged, which further increases the efficiency of minimum quantity lubrication thanks to the fast-switching coaxial solenoid valve.

- Fast response time: These valves can react within milliseconds, which is particularly important in highly dynamic machining processes where the lubricant must be provided at exactly the right moment.

- Energy saving: The fast switching speed means that lubricant is only provided when it is actually needed. This reduces the energy consumption of the entire system.

- Lower wear and maintenance costs: The precise control of the lubricant quantity and time results in less wear and less maintenance work for the solenoid valves themselves.

Summary

The combination of minimum quantity lubrication with fast-switching solenoid valves from Bavaria Fluid Systems optimizes lubricant usage, improves machining quality and contributes to more sustainable, efficient and cost-effective production. This technology is particularly valuable in modern, high-precision production environments where both environmental protection and cost reduction play a crucial role.